Ersa GmbH

Booth number: HALL 2 - H2.A38

www.ersa.com

About us

Since obtaining the first patent for an electric soldering iron in 1921, Ersa has been driving innovation in electronics manufacturing: We have digitized manual soldering (i-CON TRACE) and developed pioneering hybrid rework systems, and the HOTFLOW, POWERFLOW and VERSAFLOW systems are leading in reflow, wave and selective soldering. Customer focus is an essential part of Ersa's DNA, which is ensured by 10 subsidiaries and an international sales & service network around the globe. As a system supplier for smart line configurations, we support megatrends such as automation and digitalization, offering high-quality assembly processes that combine intelligent press-fit technology with VERSAPRINT 2 TIM (Thermal Interface Material). Our innovation, your solution. What are your requirements?

Address

Leonhard-Karl-Str. 24

97877 Wertheim

Germany

E-mail: info@ersa.de

Phone: +49 9342 8000

Internet: www.ersa.com

Plot No. 16A, Bommasandra Industrial Area, Bommasandra Attibele Hobli, Anekal Taluk

560099 Bangalore

India

E-mail: india@kurtzersa.com

Phone: +91 973 9545461

Internet: www.ersa.com

Contact person:

Tobias van Rossem

E-mail: tobias.rossem@kurtzersa.de

Dietmar Wolpert

E-mail: dietmar.wolpert@kurtzersa.de

HR 600 P – high-precision automated rework

The Ersa HR 600 P rework system is focused on precision and automation. It reliably processes small SMT components and BGA sizes of up to 60 x 60 mm.

Key Features:

PCB sizes up to 642 x 423 mm

Over 6 kW heating power: 800 W top-side hybrid heating head, 5,400 W bottom-side IR heating in 6 zones

Intuitive graphic user interface for optimal temperature profiles

Effective non- contact removal of residual solder with Auto-Scavenger. Minimal residues (~20 µm) on the cleaned pads provide for successful component installation.

The HR 600 P is available in different versions, e.g. with a lowered heating cassette creating free space of up to 65 mm on the underside of the assembly. The Auto Scavenger module can be retrofitted separately. Regular software updates ensure future-proof and efficient use.

Your Advantages:

Highly automated rework platform

Reliable removal of residual solder

Suitable for large assemblies

Flexible heating technology

Future-proof operating software

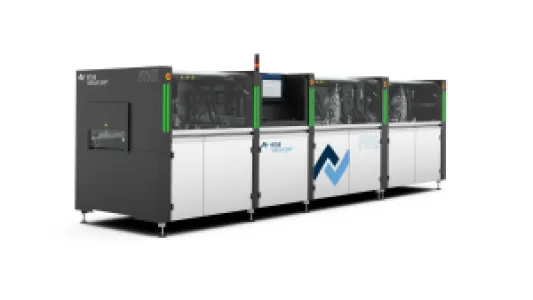

VERSAFLOW FIVE – redefinition of selective soldering

The VERSAFLOW FIVE offers the best soldering quality, combining innovative technology with maximum flexibility and energy efficiency. It is ideal for complex mixed assemblies and variable production volumes.

Key Features

VERSAFLEX 2.0: soldering module with 2 independent solder pots that allow for parallel processing of different soldering tasks without any waiting time

Extended PCB format flexibility: Processing of flat assemblies up to 685 mm in length, or two assemblies up to 320 mm

Matrix heating system: Individually controllable IR emitters in 6 segments

Automated systems: Self-cleaning flux nozzles and an automatic nozzle changer reduce downtime and increase process reliability.

Visual status display per module: LED strips allow for quick identification of operating status.

Your Benefits:

High flexibility & productivity

Highest soldering quality due to increased process reliability

Minimized consumption of resources

Reduced standstill- & maintenance time

Future-proof investment due to innovative technology

POWERFLOW FIVE – Next-generation wave soldering

POWERFLOW FIVE ensures high efficiency and flexibility with innovative technologies. It realizes high throuput even with complex assemblies.

Key Features:

Solder module with dynamic Z-axis control: more flexibility for sequential soldering and the use of solder masks

SMART WAVE GUARD: Regular monitoring and automatic adjustment of the wave height

Hybrid heating technology: increases heat transfer efficiency by up to 30% while consuming the same amount of energy

SMART IR RADIATION: intelligent standby mode reduces energy consumption by up to 10%

SMART ELEMENTS® technology: Extends operating time to the next cleaning cycle by up to 30% and improves soldering quality

Low-maintenance heavy-duty conveyors: for assemblies weighing up to 25 kg

Your benefits:

Reliable and reproducible soldering results

Energy savings due to smart heating technology

Minimal maintenance costs due to increased maintenance intervals and easy-to-change parts

Diverse interfaces

POWERFLOW ONE – your entry into wave soldering with Ersa

The compact POWERFLOW ONE, measuring just 2.60 m in length, is the cost-effective entry into the Ersa wave soldering portfolio, focusing on the essentials and combining excellent value for money with proven Ersa quality. The basic version has one wave former and is designed for stand-alone operation with a soldering frame. The reduced solder pot volume supports cost-efficient operation. Optional extensions enable upgrades up to high-performance inline operation.

Key Features

• Small footprint: only 2.60 m in length

• Powerful preheating module with 3 cassettes (2x medium wave, 1x IR emitter)

· Ersa KE.ON: State-of-the-art software technology for system control

· Proven Ersa solder pot technology with a volume of only 320 kg

• Nitrogen option

• Optional finger conveyor

• Optional inline capability

Your Benefits

• Cost-efficient operation

• Minimized downtime and maintenance times

• Ideal for smaller electronics manufacturers

• Access to the global Ersa service network

VERSAFIT ONE – semi-automatic press-fit machine

The VERSAFIT ONE is a semi-automatic system for press-fit installation of IGBT modules or high-pin-count connectors in power electronics. It combines maximum precision with a compact design and excellent value for money.

Key Features:

• 100% process reliability: Complete monitoring of the press-fit process with reproducible results

• Compact design: Ideal when space is limited

• High flexibility: Quick and easy manual tool change, customized recipes

• Versatile applications: Processes assembly sizes of up to 610 x 610 mm and weighs up to 10 kg

• Sustainable traceability: Optional traceability package for complete process traceability

Your Benefits:

• Powerful and reliable press-fit technology with a compact footprint and attractive price

• Worker-independent press-fit process without force

• Variability through quick tool changes

• Scalable production from prototyping to medium series, addition to inline systems