UniverCell Holding GmbH

Booth number: HALL 2 - H2.A35

www.univercell.group/de

About us

UniverCell develops and produces high-quality electrodes and battery cells, custom-made for specific applications. Quality made in Germany.

We are a manufacturer of electrodes and battery cells driven by innovative technologies. Our expertise in chemistry, process engineering, and advanced technology helps bring product ideas to life.

Address

Konrad-Zuse-Ring 1

24220 Flintbek

Germany

E-mail: contact@univercell.group

Phone: +49 157 80619954

Internet: www.univercell.group/de

Contact person:

Marcus W. Krueger

E-mail: marcus.krueger@univercell.group

Florian von der Wense

E-mail: florian.wense@univercell.group

Products & Services

Energy cells from pouch to cylindrical format

Electrode coating

21700 cells

UniverCell’s 21700 lithiumion cells are engineered to deliver superior energy density, outstanding cycle life, and exceptional safety. Our tabless design features maximum power performance while ensu ring exceptional thermal behavior. By selecting next-generation battery cell materials, they are designed for demanding future applications and maximum fl exibility – made in Germany, ready for the world.

Pouch Cells

UniverCell’s pouch cells are designed for fl exibility in shape, capa city, and performance. Their lightweight, compact form allows for tailor-made solutions in applications with specific spatial or energy requirements. Using advanced stacking techniques and custom chemistries, we achieve outstanding cycle life, safe ty, and energy density — making our pouch cells ideal for high-end mobility, aerospace, and stationary storage systems.

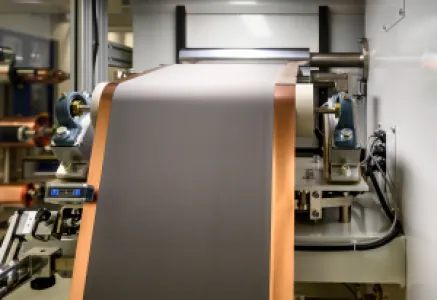

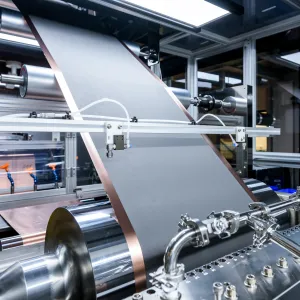

Electrode coating pilot production

UniverCell’s pilot production line is the critical interface between research and mass production. It allows us to develop, test, and refi ne new materials, chemistries, and processes under conditions that closely replicate industrial-scale manufacturing. This line provides the fl exibility to validate electrode formulations, optimize coating and drying parameters, and assess scalability — all without interrupting serial production. It also enables customer-specific prototyping: whether developing a novel cell design, testing unconventional chemistries, or adapting to unique form factors, our pilot line ensures that innovations are production-ready before full-scale rollout.

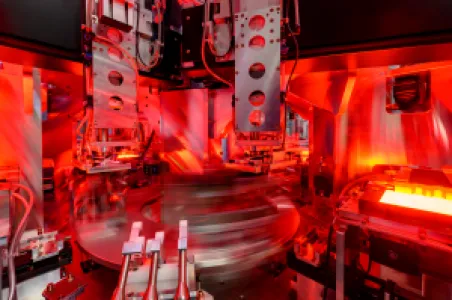

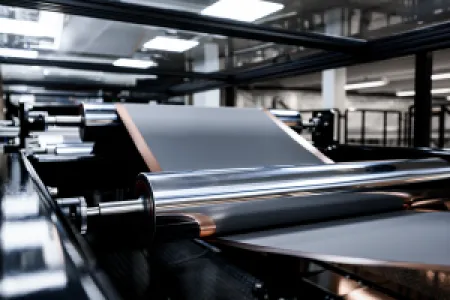

Electrode mass production

Our mass production line is built for industrial-scale manufacturing. With a capacity of 30,000 meters per day, it enables high-throughput coating and cell assembly — while maintaining tight quality control at every step. Designed for fl exibility and reliability, the line accommodates a range of cell formats and chemistries, supporting everything from niche applications to large-volume series. Whether for energy storage, e -mobility, or aviation, we scale production without compromising on safety, performance, or consistency. Automated systems, in-line monitoring, and robust process engineering ensure stable output and fast response to evolving customer demands — all made in Germany.